Version 2.0

The big update for version 2.0 was aluminum instead of plexiglass.

![Image]()

![Image]()

![Image]()

![Image]()

There will be a version 3, eventually... version 3 will include a gas strut and better latches.

Version 1.0

![Image]()

![Image]()

![Image]()

![Image]()

\/ \/ OUTDATED INFORMATION BELOW \/ \/

This is more of a "How I'm Gonna Do It" thread. I'm gonna go through the parts list and a mock procedure. Then all you smart, mechanically inclined cookies can critique it and I'll begin the process for real.

![Image]()

There is a separate thread on this project here . If you want to talk about the utility or feasibility of a gullwing window please take it over there and keep this thread technical.

I found a how-to over on NissanPatrol.com.au here but unfortunately I don't speak Australian so that's all the credit they're getting.

Goals:

Phase I - DONE

-Research

-Measure (amount of moulding, panel size, estimate weight/forces required)

-Acquire parts

Phase III - DONEZO

-Installation

Anticipated install date: 04/01/2017

The big update for version 2.0 was aluminum instead of plexiglass.

There will be a version 3, eventually... version 3 will include a gas strut and better latches.

Version 1.0

\/ \/ OUTDATED INFORMATION BELOW \/ \/

This is more of a "How I'm Gonna Do It" thread. I'm gonna go through the parts list and a mock procedure. Then all you smart, mechanically inclined cookies can critique it and I'll begin the process for real.

There is a separate thread on this project here . If you want to talk about the utility or feasibility of a gullwing window please take it over there and keep this thread technical.

I found a how-to over on NissanPatrol.com.au here but unfortunately I don't speak Australian so that's all the credit they're getting.

Goals:

-Rear cargo area access from the side (primary objective)

-Decreased visibility into cargo area (this is going on the driver's side so I don't need to see out)

-Locking

-Theft resistant (since nothing is theft proof)

-Does not whistle in wind

-Does not leak when it rains, snows, freeze thaw, etc

-$100 out the door-Decreased visibility into cargo area (this is going on the driver's side so I don't need to see out)

-Locking

-Theft resistant (since nothing is theft proof)

-Does not whistle in wind

-Does not leak when it rains, snows, freeze thaw, etc

Phase I - DONE

-Research

-Measure (amount of moulding, panel size, estimate weight/forces required)

-19"tall x 26.25" wide

-87" circumference (~7.5')

-use 1/8" plexiglass

-Look at upper support for hinges (is the mounting surface strong enough)?-87" circumference (~7.5')

-use 1/8" plexiglass

-upper mounting surface is very sturdy. Self tapping sheet metal screws will be a big winner here

-Drill right through headliner and into metal frame. Easy as pie.

-Is the window flat (would make things so much easier)?-Drill right through headliner and into metal frame. Easy as pie.

-No, it has a small bend. We're gonna have to do some forming of acrylic sheet using my mom's oven

-Is a frame necessary?-No. 2 brackets will need to be installed on the bottom edge for compression latches

Phase II - DONE-Acquire parts

-(1) Acrylic sheet (36" x 24")

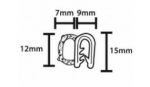

-(2) Rubber trim/weatherstrip 8 ft sections

-(2) Compression latch, 1 locking, 1 regular

-Hardware

-(1) Silicon adhesive/liquid nails

-(2) Rubber trim/weatherstrip 8 ft sections

-(1) bulb style for vehicle side to promote weather resistance)

-(1) C style for the edge of plexiglass

-(2) Hinges-(1) C style for the edge of plexiglass

-(2) Compression latch, 1 locking, 1 regular

-Hardware

-(10) self tapping sheet metal screws

-(10) pan head spanner screws (for secure connection of hinge to window)

-(1) 24" x 36" vinyl wrap-(10) pan head spanner screws (for secure connection of hinge to window)

-(1) Silicon adhesive/liquid nails

Phase III - DONEZO

-Installation

[ ] -Remove window

[ ] -Remove glass from face and hands from broken window

[ ] -Place hinges

[ ] -Drill hinge holes in plexiglass

[ ] -Cut holes for compression latches

[ ] -Dry fit

[ ] -Apply carbon fiber wrap

[ ] -Apply molding

[ ] -Dry fit

[ ] -Glue

[ ] -Assemble

[ ] -Crack a cold one

[ ] -Remove glass from face and hands from broken window

[ ] -Place hinges

[ ] -Drill hinge holes in plexiglass

[ ] -Cut holes for compression latches

[ ] -Dry fit

[ ] -Apply carbon fiber wrap

[ ] -Apply molding

[ ] -Dry fit

[ ] -Glue

[ ] -Assemble

[ ] -Crack a cold one

Anticipated install date: 04/01/2017